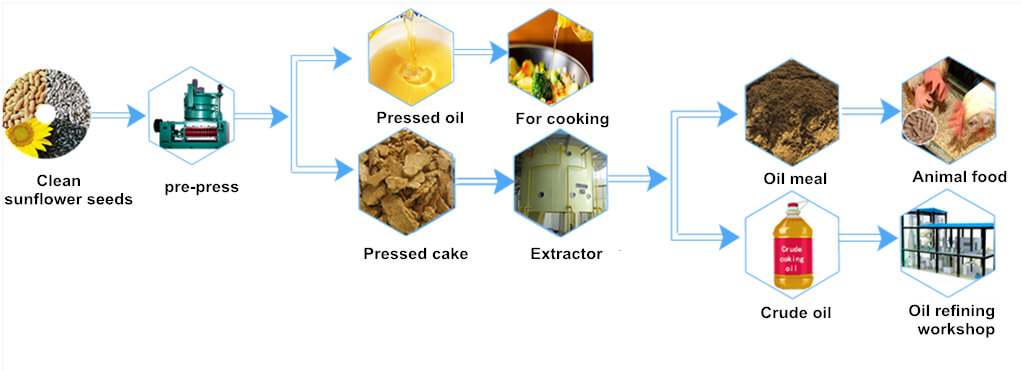

We can provide 100-5000T/D complete sunflower oil production line. Sunflower oil production line includes seed pretreatment, oil extraction (using pressing and/or solvent extraction), and crude oil refining. The pretreatment stage prepares the seeds by cleaning, dehulling, and flaking them. Oil extraction follows, where seeds are either mechanically pressed or subjected to solvent extraction to remove the oil. We provide tailored solutions for small scale, medium scale and large scale sunflower oil production line according to your actual situation.

Brand

QIE

Raw Material

Sunflower

Capacity

100-5000TPD

100-5000TPD

Customized Sunflower Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

In sunflower oil production, the choice between mechanical pressing and solvent extraction depends on factors like plant capacity. For the sunflower oil mill plants under 50 TPD capacity, the mechanical screw oil pressing is ok. For the oil mill plants with a capacity above 50 TPD, The solvent extraction method is used together with a mechanical press.

The sunflower oil solvent extraction plant is part of the sunflower oil processing plant, which is designed to extract oil directly from pressed sunflower oil. After the sunflower oil solvent extraction plant, the residual oil content in the sunflower oil is less than 1%. The pretreated sunflower flakes are sent to the sunflower solvent extraction plant. The plant uses a type of solvent (normal hexane) to absorb the sunflower oil, and then machines separate the solvent from the crude sunflower oil. The solvent is used for recycling, and the crude sunflower oil is refined in an oil refinery plant.

Pressed cake→Solvent extraction system→D.T.D.C system→Condenser system→Recovery system→Crude sunflower oil

using N-hexane to react with puffing sunflower materials, then you can get two parts: the mixture of solvents and oil called miscella oil and the mixture of solvents and meal called wet meal.

D.T.D.C means desolventizer, toaster, dryer and cooler, which is mainly used to separate the solvents from the wet meal, then the dried meal will be sent to meal silo for storage.

since miscella oil contains solvents, we need to separate the solvents from the crude sunflower oil by first evaporation, second evaporation and stripping tower, then we can condensate the oil and pump it into a crude oil tank, and you can choose to sell the crude oil to the refinery factory or you can set up a sunflower oil refinery plant by yourself.

Usually producing one ton crude sunflower oil through the sunflower oil solvent extraction method needs around 4kg solvents. Considering of cost-effectives and environmental protection, we add this system to recycle the solvents by condensing it and collecting it for reuse.

Batch type oil refining plant: Capacity is 1~30 TPD. It featured less investment, convenient operation, and a small footprint.

Semi-continuous Oil Refining Plant: Capacity is 30~50 tons TPD. It has the advantages of low power consumption and a better refining rate than batch-type.

Full continuous oil refining plant: Capacity is 50 - 5,000 TPD. It is suitable for large-scale sunflower oil plants.

Degumming Process

Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in degumming section of sunflower oil refinery plant, we use the hot water to wash crude oil for two-three times to remove these impurities.

Neutralizing/Neutralization Proces

The crude oil is fed into the neutralizer and mixed with small amounts of degumming agent such as phosphoric acid to help remove gums.Free fatty acids are removed from the oil by adding caustic soda and heating it at 60˚ then stirring the mixture. Heating forms soap base, which is then precipitated and collected, and washed with water to remove alkaline particles.

Decolorizing Process

The neutralized oil requires bleaching machine to get rid of colors. This is done by adding the oil in a bleacher machine whereby it is heated to remove any moisture it might have and then mixed with earth bleach and activated carbon. These two properties absorb any colors after which the oil is passed through a filter to separate oil from earth bleach and carbon. The result is golden light oil.

Deodorizing Process

The golden light oil has unpleasant odors which result from materials such as aldehydes, ketones, tocopherols and phenols among other odiferous elements. Deodorizing process of sunflower oil refinery plant helps remove these odors by adding the oil in the deodorizer and heating it above at very high temperature and under very high vacuum. This deodorizing process helps get rid of all odors.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Group has successfully installed cooking oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes cooking oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Group ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn More