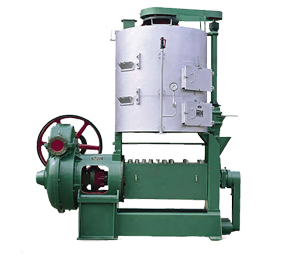

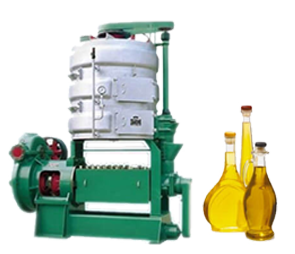

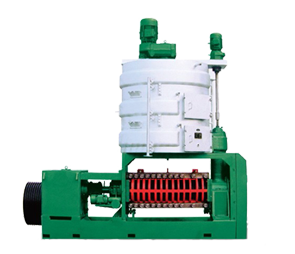

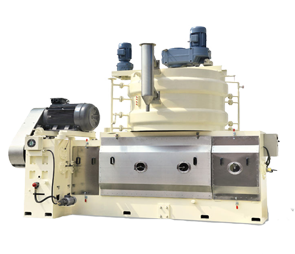

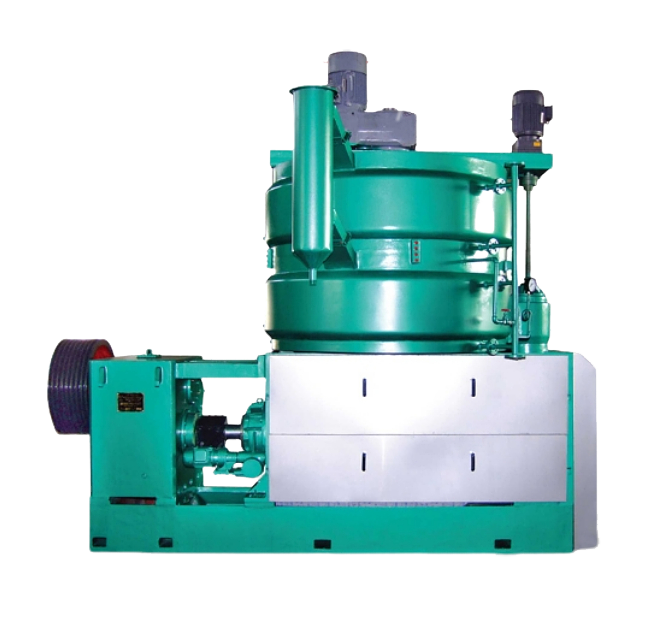

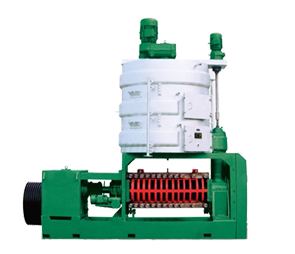

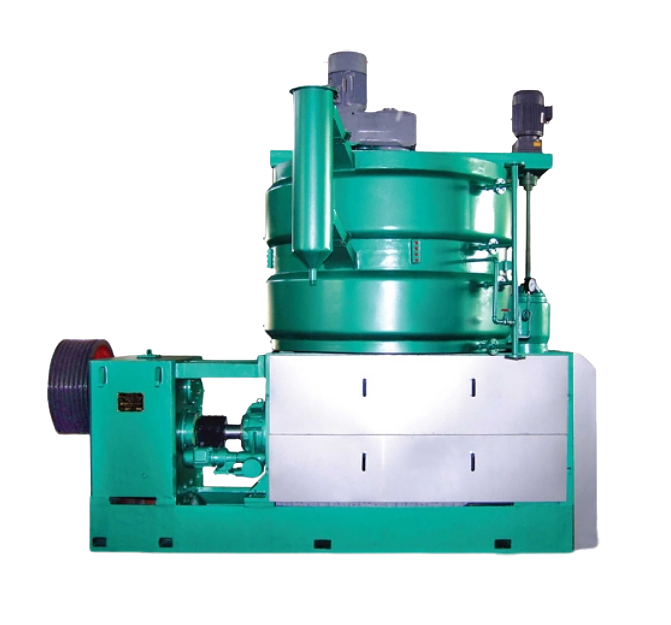

The Integrated Oil Press Machine is an advanced, multifunctional oil extraction system that combines oil pressing and filtration in a single unit. Designed for efficiency and convenience, it is ideal for small to medium-scale oil mill plants seeking high-quality oil with minimal labor and processing time. This versatile oil press machine can process a variety of oilseeds, including peanuts, sesame seeds, soybeans, rapeseeds, sunflower seeds, coconut meat, flaxseeds, mustard seeds, etc.

Processing Capacity: 1-30 T/D

Processing Capacity: 1-30 T/D Residual Oil Rate: ≤7

Residual Oil Rate: ≤7

all machine can be customized according to customers' needs.

1. Oilseed Feeding HopperGuides raw materials into the press chamber with consistent flow, ensuring uninterrupted operation.

2. Oil Pressing Chamber with Screw PressEquipped with a high-torque screw press that crushes and compresses oilseeds for maximum oil extraction. Heat-regulated chamber enhances oil flow and minimizes residue.

3. Integrated Oilseeds Heating SystemIt preheats seeds and stabilizes pressing temperatures, improving oil yield and quality. The temperature settings are adjustable to accommodate different types of seeds.

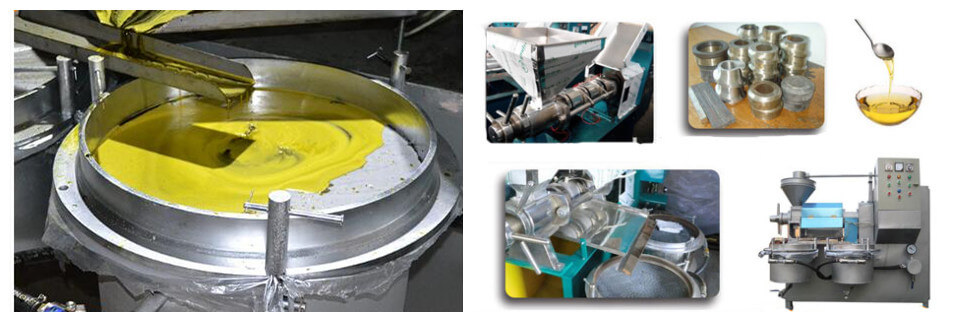

4. Crude Oil Filtration SystemThe vacuum edible oil filtration unit removes fine particles and impurities directly after pressing. Produces clean, transparent oil ready for packaging or further processing.

5. Oil Outlet and Collection SystemPositioned directly beneath the oil press machine for efficient collection of clean oil. Spill-free design reduces waste and keeps the workspace tidy.

6. Residue Discharge SystemAutomatically separates and ejects oilseed cakes for efficient waste management. Oil cakes are compact and can be repurposed as livestock feed or organic fertilizers.

7. Control PanelThe control panel interface for monitoring and adjusting key parameters like temperature, pressing speed, and filtration.

QIE Group is a professional small cooking oil mill plant manufacturer. We can provide screw oil press machine, small scale oil mill plant, cooking oil production line and oil refinery machine, turnkey cooking oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

| Model | Capacity | Power | Dimension | Weight |

| 6YL-80A | 2-3 T/D | 5.5 KW | 1760*1050*1850 MM | 600 KG |

| 6YL-95A | 3-5 T/D | 7.5 KW | 2050*1050*1850 MM | 940 KG |

| 6YL-120A | 4-6 T/D | 11 KW | 2220*1050*1850 MM | 1200 KG |

| 6YL-120CA | 7-9 T/D | 15 KW | 2340*1050*1850 MM | 1300 KG |

| 6YL-130A | 9-12 T/D | 18.5 KW | 2450*1100*1950 MM | 1500 KG |

| 6YL-160A | 13-18 T/D | 22 KW | 2600*1200*1950 MM | 1680 KG |

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

Integrates oil pressing and filtration into one compact unit, saving space and reducing the need for additional equipment. Delivers clean, ready-to-use edible oil in a single step.

Fully Automated OperationAutomatically manages raw material feeding, oil pressing, and filtration for seamless processing. Reduces the need for manual intervention, allowing operators to focus on other tasks.

High Oil Yield and QualityOptimized screw pressing and controlled heating enhance oil extraction, leaving minimal residue in the oilseed cakes. Built-in filtration ensures the final oil is clean, transparent, and free of impurities.

High EfficiencyCombines mechanical pressing and immediate filtration, significantly reducing production time. Achieves high oil yields for various oilseed types, including peanuts, sesame, rapeseed, sunflower seeds, soybeans, etc.

User-Friendly OperationSimple controls allow even inexperienced operators to achieve professional results. Automatic feeding and continuous operation enhance productivity. Features a digital control panel for easy adjustments to pressing temperature, speed, and filtration settings.

High-Quality Edible Oil OutputIntegrated filtration removes impurities, producing clear, high-grade oil suitable for edible or industrial applications.

Compact and Durable ConstructionAll-in-one construction combines multiple functions in a single unit, ideal for operations with limited space. Built with food-grade stainless steel and heavy-duty materials for long-lasting performance. Designed to fit seamlessly into small production spaces.

Our cooking oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the oil production equipment and cooking oil production lines we manufacture. Whether you need a single oil production equipment or a complete oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

QIE Group is a large-sizd joint-equity enterprise specializing in the production of cooking oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for oil production. Customize the cooking oil processing equipment capacity according the different customers requirements.