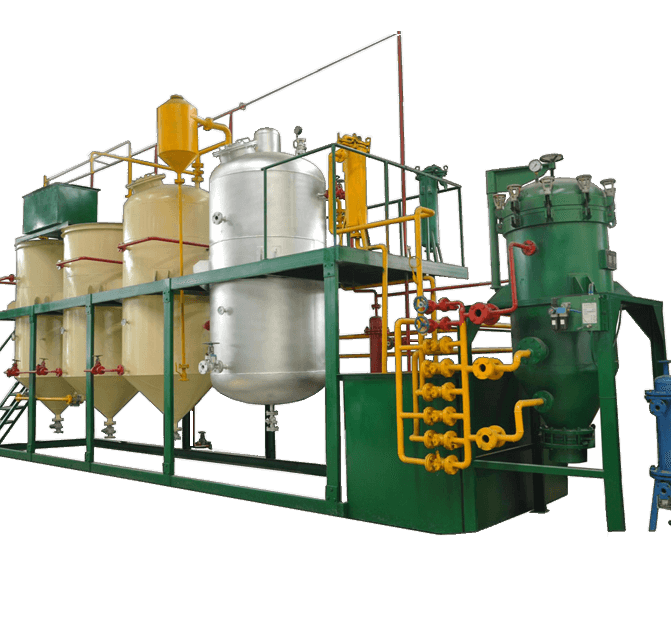

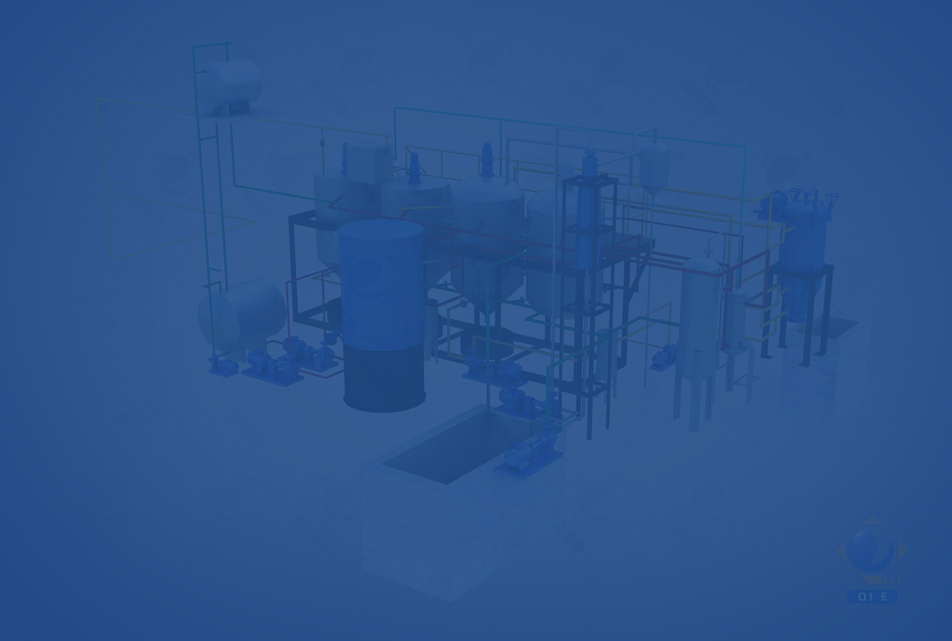

Cooking Oil refining is divided into physical methods, chemical methods, and physical chemistry methods. For a certain crude oil, which methods should be used in the refining process, generally depends on the quality of crude oil, the application of refined oil, the refining process budget, and the advanced nature of equipment, and both a single oil refinery machine and the entire oil refining line are available from us to do physical & chemical refining. The complete edible oil refining process mainly includes filtration, degumming, deacidification, vacuum dehydration, decolorization, deodorization, dewaxing, and polishing filtration.

Processing Capacity: 1-10T/D

Processing Capacity: 1-10T/D Raw Material: Crude Cooking Oil

Raw Material: Crude Cooking Oil

all machine can be customized according to customers' needs.

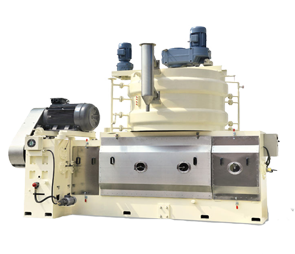

1.The batch-type oil refining line is cut by a plasma CNC cutting machine and welded together by automatic welding equipment. The weld has a uniform forming and exquisite appearance which can reach customer satisfaction. Tight structure and a small footprint.

2.The entire production line is made of food-grade stainless steel and through a polishing process. Long service time and conform to national food machinery standards.

3.The machine uses the heating coil as a heat source. Small size, compact structure, high heat transfer efficiency, good mechanical strength, good adaptability, and high refining rate.

4.The machine is equipped with a ball valve, which has small fluid resistance, strong abrasion resistance, good sealing performance, and long service life.

5.The operating data are all displayed by the instrument, automatic measurement, and control for temperature, pressure, flow, and liquid level, simple & safe operation.The ordinary staff after telephone training can work on the machine.

6.The small oil refining production line can achieve oil dephosphorization, dealkalization, and dehydration functions, and it can also achieve constant temperature decolorization according to users’

7.The oil-heating furnace has a strong adaptability to fuel, the fuel can be rice husk, firewood, coal, etc. Less investment and good effect.

QIE Group, as a premier manufacturer of oil refining facilities in the industry, is committed to delivering clients refined sunflower oil plants tailored to their specific needs. We offer a comprehensive suite of services that cover the entire oil refining process, encompassing plant design, equipment selection and production, on-site installation and commissioning, operator training, and more. Here, we present the complete steps of our sunflower oil refining production for your consideration and inspiration.

| Steam consumption | 700KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Alkali | acid valuex1-3kg/T oil |

| Circulating water cooling water yield | 150M3/ |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses | acid valuex1.2 (chemical refining) acid valuex 0.6 (physics refining) |

| Bleaching losses | the quantity of bleaching earth×0.25% |

| Deodorization loss consumption | ≤0.5%≤0.5% |

| Refining rate | 1-refining consumption |

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

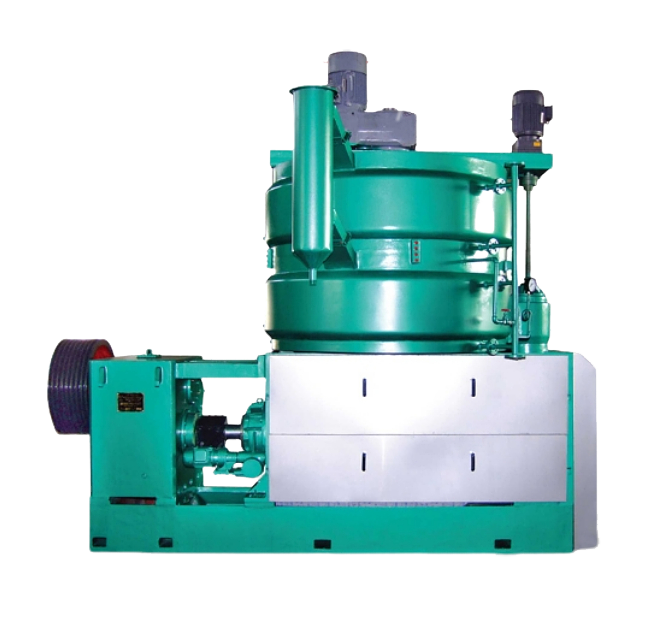

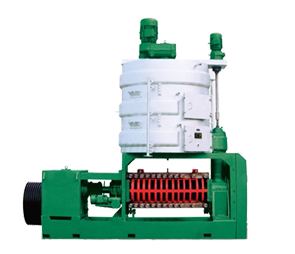

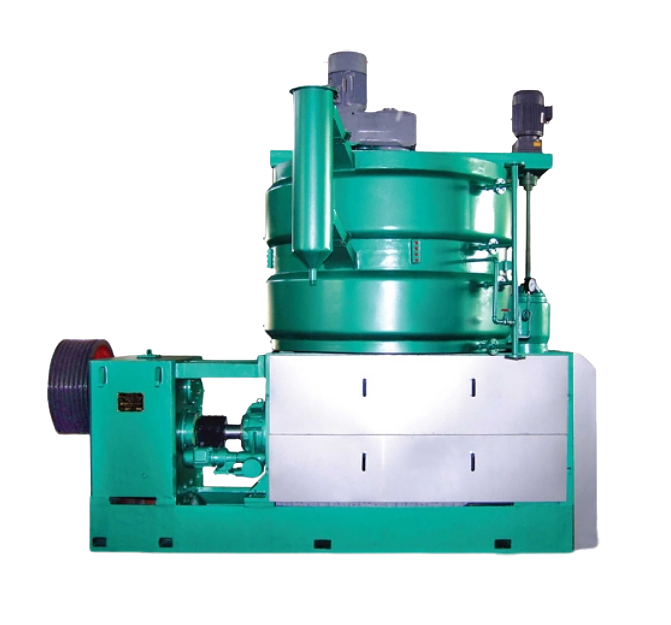

* Two refining tanks work interactively or work simultaneously to speed up the refining time

* The decolorization tank works under vacuum and automatically inhales adsorbent (white soil)

* Automatic slag filter can filter the white soil mechanically, no manual operation

* Soap foot salting out tank is used for refining foot to get part of clean oil and reduce the consumption of refined oil.

* Heat conduction oil furnace is equipped with steam generator, without the need for steam boiler

* Other auxiliary equipment compressors, vacuum pumps, infusion pumps, electronic control cabinets and operating platforms for installation materials are all included; * Users do not need to purchase other equipment to use.

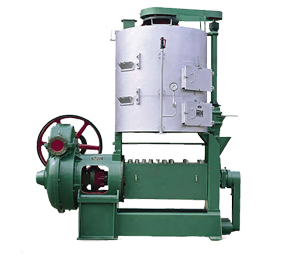

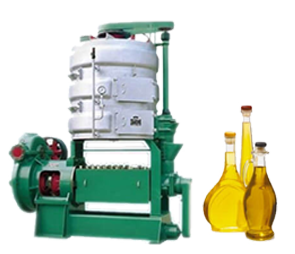

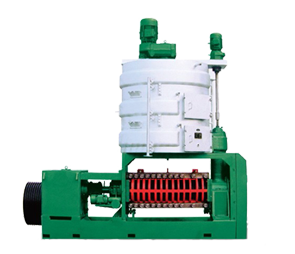

Our cooking oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the oil production equipment and cooking oil production lines we manufacture. Whether you need a single oil production equipment or a complete oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

QIE Group is a large-sizd joint-equity enterprise specializing in the production of cooking oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for oil production. Customize the cooking oil processing equipment capacity according the different customers requirements.