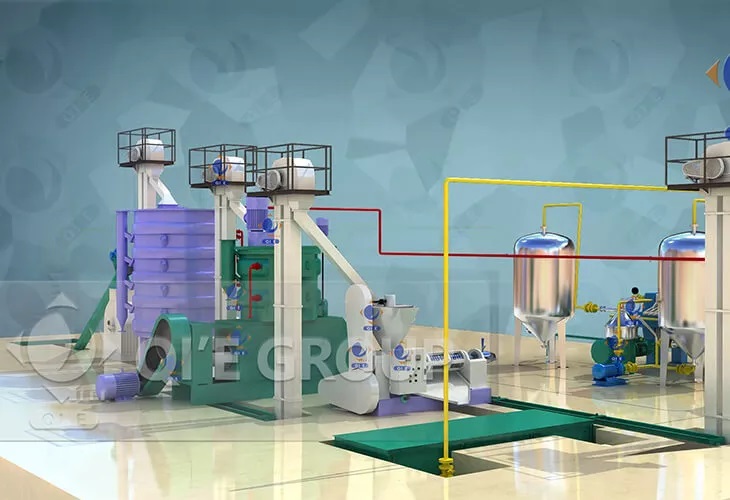

Coconut Oil Production Line adopts twice pressing technology to produce coconut oil from the dried copra. The coconut oil production line mainly includes coconut oil pretreatment and oil pressing process, refining process. The pressed coconut cake can be used as animal feed. The moisture content of dried coconut for pressing should be controlled at 7%-10%. We can offer 10-500TPD coconut oil processing machine.

Brand

QIE

Raw Material

Copra

Capacity

10-500TPD

10-500TPD

Customized Coconut Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

copra →cleaning →crushing→softening→ pre pressing → twice pressing →filteration → crude oil tanks → refined section → refined coconut oil

The crude coconut oil obtained after extraction may contain impurities, including free fatty acids (FFAs), pigments, and odors. Coconut oil refining is mainly done by the physical refining process, which can be efficiently deodorized and further contribute to the improvement of oil quality by removing impurities, odor, and free fatty acids.

Crude Oil Degumming & De–acidification Section

The degummed oil enters the mixing tank and the clay is added for fully mixing. The mixture of oil and clay is pumped into the bleaching tower. By heating under vacuum in the bleaching tower, the pigment in the oil is absorbed on the bleaching earth. The mixture is then pumped to the leaf filter and the waste clay is removed.

Crude Oil Deodorization Section

By steam distillation under high vacuum, the bleached oil is deodorized in the deodorization tower. The free fatty acids and unpleasant odor are removed. The removed fatty acid will be collected by the catcher and later to be used as the by-product.

Bleaching

The degummed and neutralized oil is mixed with bleaching earth and then the mixture is sent into the bleaching tower in the cottonseed oil refinery plant. By heating under vacuum, the residual gossypol and other pigments in the oil are adsorbed on the clay. The mixture from the bleaching tower is pumped into the leaf filter to remove the waste clay.

coconut oil refinery machines style

1. batch refining (1-20 TPD)

2. semi-continuous refining(20-50 TPD)

3. fully continuous refining(50-600 TPD)

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Group has successfully installed cooking oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes cooking oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Group ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn More