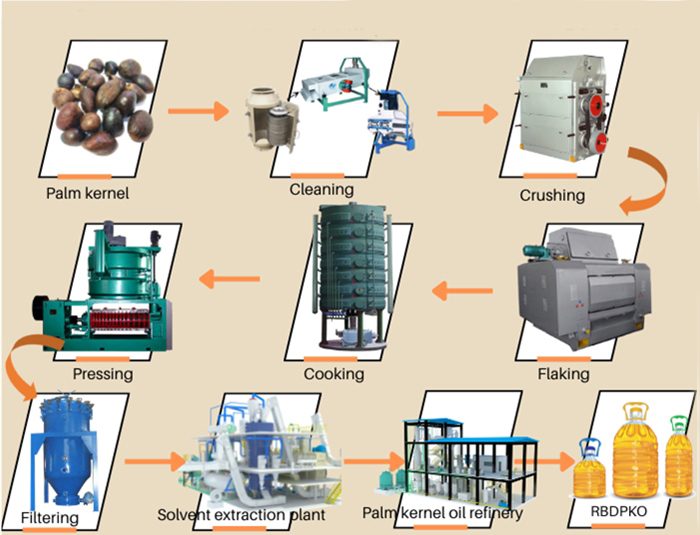

We are professional palm kernel oil production machine manufacturer, provides complete palm kernel oil production line with input capacity 1-2000 tons per day. Total palm kernel oil production process includes three workshops: Palm kernel oil pretreatment and pressing workshop, palm kernel oil solvent extraction workshop and palm kernel oil refining workshop. Whether you are expanding your current palm oil mill plant or setting up a new palm oil plant, our complete, state-of-the-art solutions cover every stage of palm oil production to maximize quality, efficiency, and yield.

Brand

QIE

Raw Material

Palm Kernel

Capacity

1-2000TPD

1-2000TPD

Customized Palm Kernel Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

Pretreatment is necessary for efficient oil extraction from raw palm kernel.

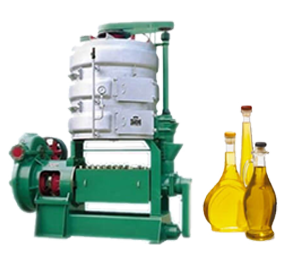

Mechanical Pressing: After pre-treatment, kernels are fed into palm kernel screw press machines that apply high pressure to extract crude palm kernel oil (CPKO). Mechanical pressing can typically extract up to 45-50% of the oil content. Equipped with the automatic temperature-controlling device and crude oil filter tank, Our integrated screw oil press operates easily and has high oil output. After pressing, the crude palm kernel oil is filtered through the filter cloth and stored in tanks temporarily. The specially designed feeder ensures the feeding is continuous and average, thus the pressing process is smooth and efficient.

Heating: Some systems employ heat to improve oil extraction efficiency, making the process smoother and increasing the yield. Heating also helps reduce the oil's viscosity, easing its flow.

Continuous Pressing: In large Palm Kernel Oil production lines, continuous pressing is used to increase the amount of oil extracted. This step may also include a secondary press to further extract oil from the residual cake.

Palm Kernel Oil Press Machine

Large Scale Palm Kernel Oil Press Machine

Palm kernel solvent extraction plant is used to extract palm kernel oil from palm kernel cake.In this part of palm kernel oil extraction plant called palm kernel oil solvent extraction, there is only less 1% oil content in the meal.

Pressed palm cake→Solvent extraction system→D.T.D.C system→Condenser system→Recovery system→Crude palm oil

Solvent (often hexane) is used to dissolve and separate the oil remaining in the press cake. This method increases yield, especially for high-capacity plants.

D.T.D.C means desolventizer, toaster, dryer and cooler, which is mainly used to separate the solvents from the wet meal, then the dried meal will be sent to meal silo for storage.

since miscella oil contains solvents, we need to separate the solvents from the crude palm oil by first evaporation, second evaporation and stripping tower, then we can condensate the oil and pump it into a crude oil tank, and you can choose to sell the crude oil to the refinery factory or you can set up a palm oil refinery plant by yourself.

Usually producing one ton crude palm oil through the palm oil solvent extraction method needs around 4kg solvents. Considering of cost-effectives and environmental protection, we add this system to recycle the solvents by condensing it and collecting it for reuse.

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

The oil degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Deacidification Process

Oil Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil.

Bleaching Process

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization Process

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Purpose: Fractionation separates palm kernel oil into liquid (olein) and solid (stearin) fractions. Olein is typically used in food, while stearin is used in non-food products, like soaps and cosmetics.

Dry Fractionation: This process crystallizes the oil without chemicals, followed by filtration to separate solid and liquid components. The dry fractionation method is cost-effective and ideal for high-purity olein.

Solvent Fractionation: Uses a solvent to improve the separation of olein and stearin, producing a high-quality product with higher purity.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Group has successfully installed cooking oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes cooking oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Group ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn More