Rice bran oil is an oil extracted from rice bran. Rice bran is a by-product obtained during the processing of rice. The rice bran oil production line includes rice bran pretreatment & expanding workshop, rice bran oil solvent extraction workshop and rice bran oil refining workshop. Our rice bran oil production lines capacity range from 10-500TPD. Customization is available to meet the unique needs of different customers, including factory layout design, machinery selection, automation systems, and energy-efficient features.

Brand

QIE

Raw Material

Rice Bran

Capacity

10-500TPD

10-500TPD

Customized Rice Bran Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

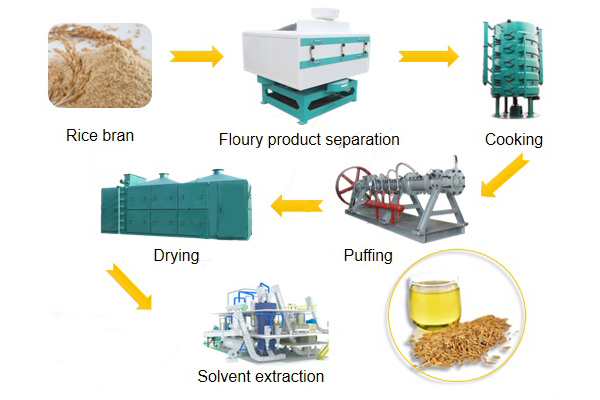

rice bran→rice bran cleaning→rice bran and broken rice separation→Cooking→Puffing→Drying→to solvent extraction workshop

After pretreatment, rice bran will be sent into rice bran oil solvent extraction plant. The extraction process is the central step where oil is separated from rice bran, typically through solvent extraction. The solvent extraction process involves multiple stages, each carefully designed to maximize oil yield while maintaining product quality. The solvent extraction process meets both economic and environmental standards, making it ideal for large-scale rice bran oil production lines.

rice bran→solvent extraction→wet meal desolventizing→evaporating and stripping→solvent recovery→crude extracted rice bran oil

The expanded rice bran enters the rotocel extractor or loop extractor in the rice bran oil extraction plant to extract the oil with a solvent. The drained wet meal is sent to the DTDC desolventizer by the wet meal scraper conveyor. The thick miscella is pumped into the miscella centrifugal separator and continuous miscella filter to remove the solid impurities, and finally pumped into the miscella holding tank.

The solvent containing wet meal discharged from the oil extractor enters the DTDC desolventizer to separate the solvent from the meal.The dried meal enters the cooling layer to lower down the temperature and is then sent to the meal storehouse for packaging. The mixed vapor from the desolventizer in the rice bran oil plant enters the shell pass of first long tube evaporator as the heat source.

The miscella from the miscella holding tank enters the first evaporator, the second evaporator and the disk stripping column in the rice ban oil plant to separate solvent and crude rice bran oil. The solvent vapor enters the condensing system. The crude oil enters the crude oil holding tank. The rice bran oil extraction plant adopts negative pressure evaporation technology, saving steam consumption and the extracted crude oil has good quality.

The solvent vapor in the rice bran oil extraction plant enters the condensing system.The condensate from the condensing system enters the water separator. The solvent separated enters the solvent holding tank for recycling use. The water separated enters the boiling tank to strip the residual solvent by direct steam.The solvent-carrying air in the rice bran oil extraction plant enters the vent gas condenser.

Crude cottonseed oil contains gossypol (about 1%), gums, and waxes, making it poor quality and unsafe for direct consumption. After refining, the cottonseed oil contains less than 0.02% gossypol, meeting food safety standards.

Degumming

This is the most important section of rice bran oil refining process, adding the water(there is little P-acid in water)to remove the gum.

Decolorization

Using alkali like(NaOH)to neutralize FFA in rice bran oil, during this refining process, it will produce soap stock, then separating it from the oil.

Decolorization

Because there is pigment in crude oil, the oil color is dark. In order to lighten oil color, we need to use the white clay to absorb the pigment away, then using vibrate filter to separate the waste clay. The oil color can be controlled by clay amount.

Deodorization

Generally speaking, the crude rice bran oil smells not good, it will affect oil storage and price. So we usually use the direct steam to take odors away. Meanwhile, about 0.5% water content in refined oil is also removed.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Group has successfully installed cooking oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes cooking oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Group ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn More